The power of reliability, fairness and efficiency in the sheet metal cutting market

With Eagle, you're not simply acquiring a fiber laser cutting system, —you’re investing in proven reliability, world- class technology, and a partnership that prioritizes your success. We are committed to providing our clients with the best all- around experience, from purchase through installation and long-term maintenance.

Eagle is rewriting success in the metal industry for clients worldwide

Clients are at the heart of our mission, fueling our drive for innovation with their success. Eagle customers have harnessed the power of fiber laser technology to transform their operations and set new standards for productivity. Their achievements are a testament to our dedication and shared vision for growth.

Client Testimonials

ABB

“We needed a high-speed device with very tough tolerance and accuracy. We realized that the Eagle iNspire was the fastest machine on the market.”

Johan Kalander,

AME Manager at IEC LV Motors, ABB - Finland

SERWISTAL

“After reviewing all possible manufacturers worldwide, many visits to trade shows and verifying offers, parameters and possibilities, but also researching users' opinions, we chose Eagle.”

Jakub Gróbarczyk,

Commercial Director / Member of the Board at Serwistal - Poland

MORGAN METAL

“I'd definitely recommend this machine to another customer that’s in our line of work. The reliability and speed is pretty hard to match. So, on a competition basis, you’ll definitely be ahead of the game.”

Richard Morgan,

Owner at Morgan Metal Corp. - Australia

For the latest sheet metal cutting and fiber laser technology, subscibe to our newsletter.

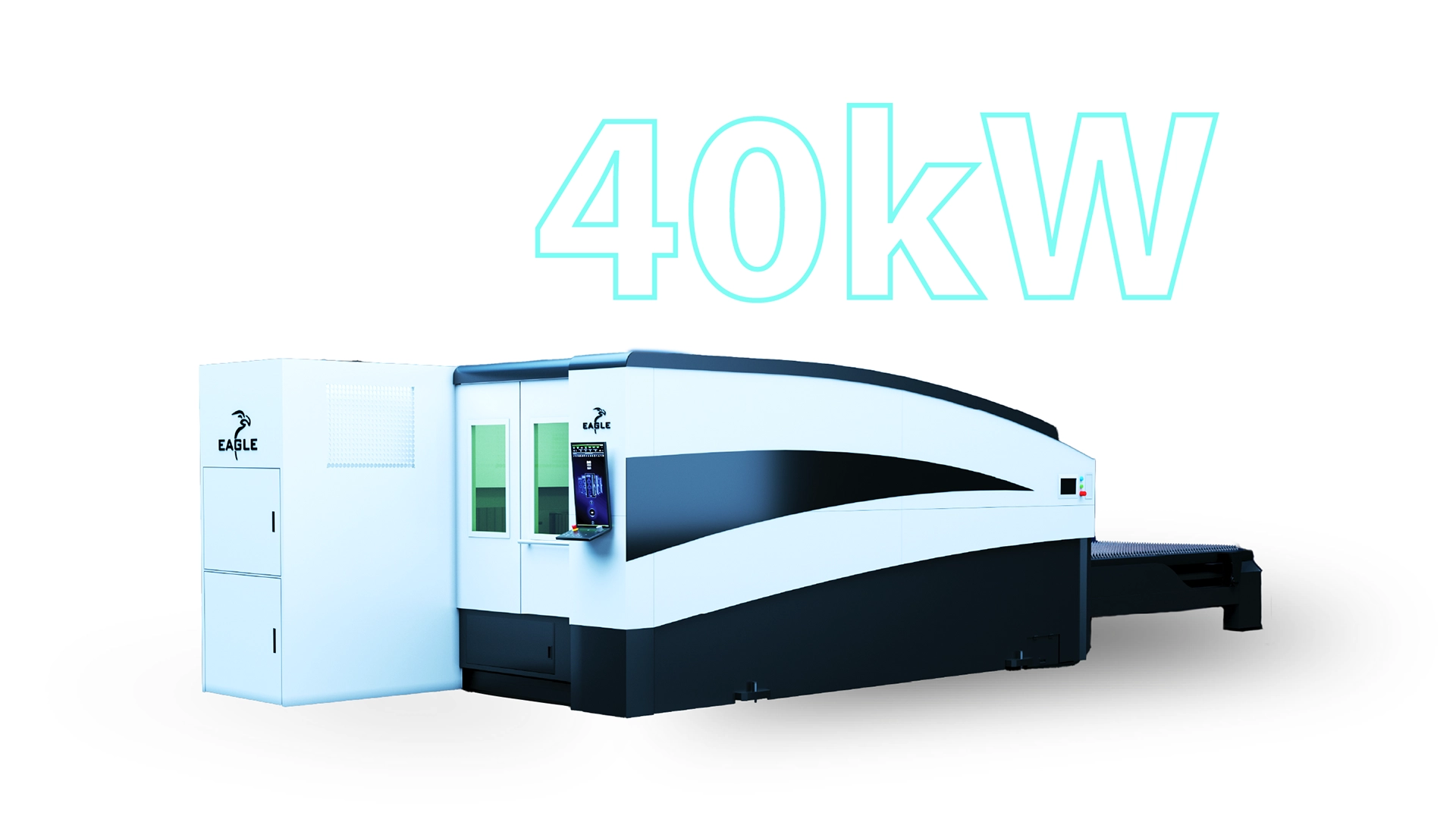

Setting a new standard in fiber laser technology

With innovation at the core of our DNA, we were the first manufacturer to invest in high-powered fiber laser cutting systems, which today reach up to 40kW of controlled and precise power. Every machine at Eagle is designed to ensure maximum productivity and efficiency from concept to construction. Today, we continue our quest to deliver only the top-performing laser cutting technology and the most innovative software on the market.

A complete solution for your business

Eagle laser cutting machines are designed to enhance efficiency, boosting your profits while reducing energy consumption and maintenance. We are devoted to developing the most productive machines with the fastest laser cutting speeds, highest acceleration, and fully automated material handling without ever compromising quality and accuracy.

Explore our product portfolio

Innovation in sheet metal cutting

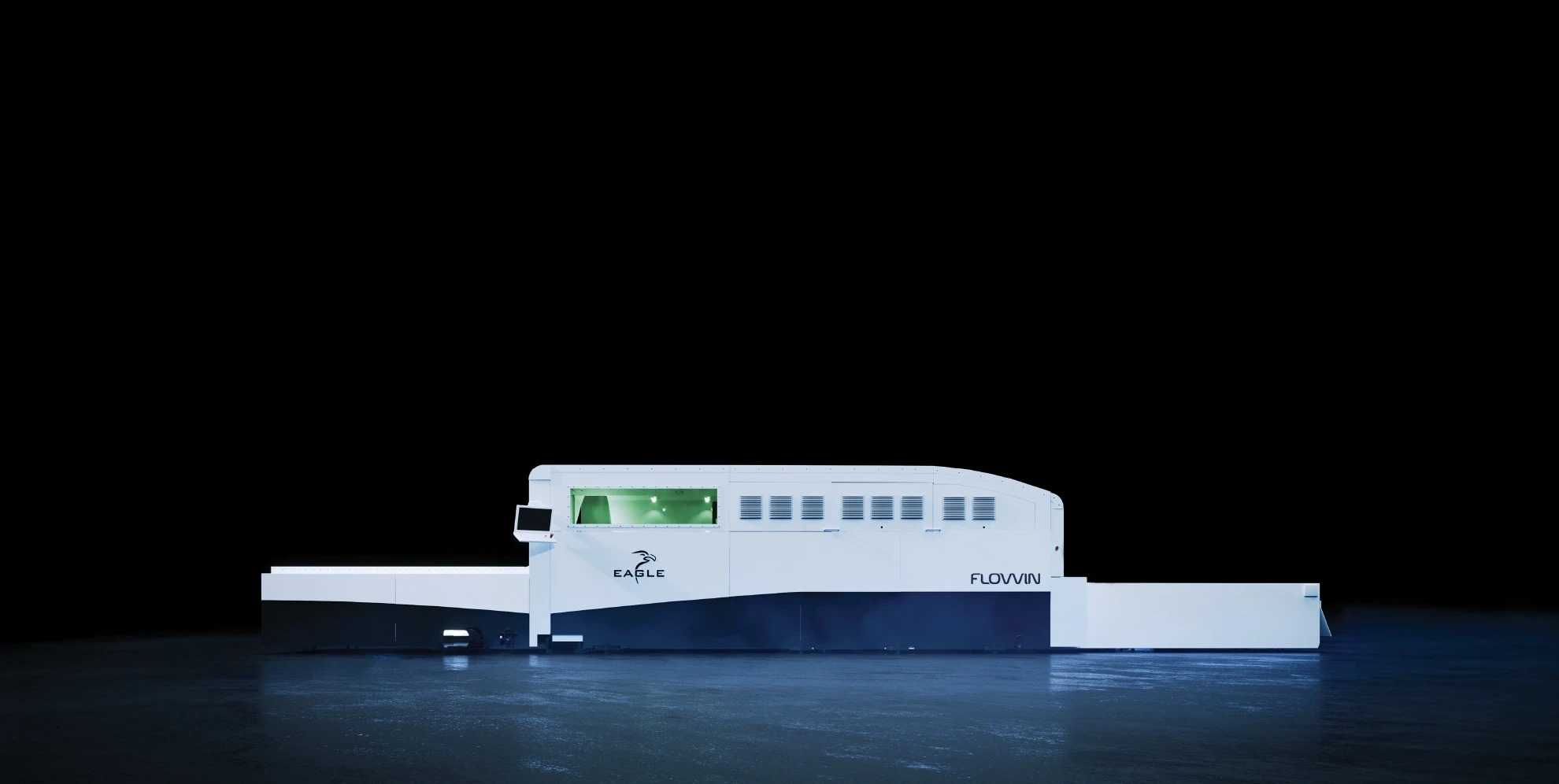

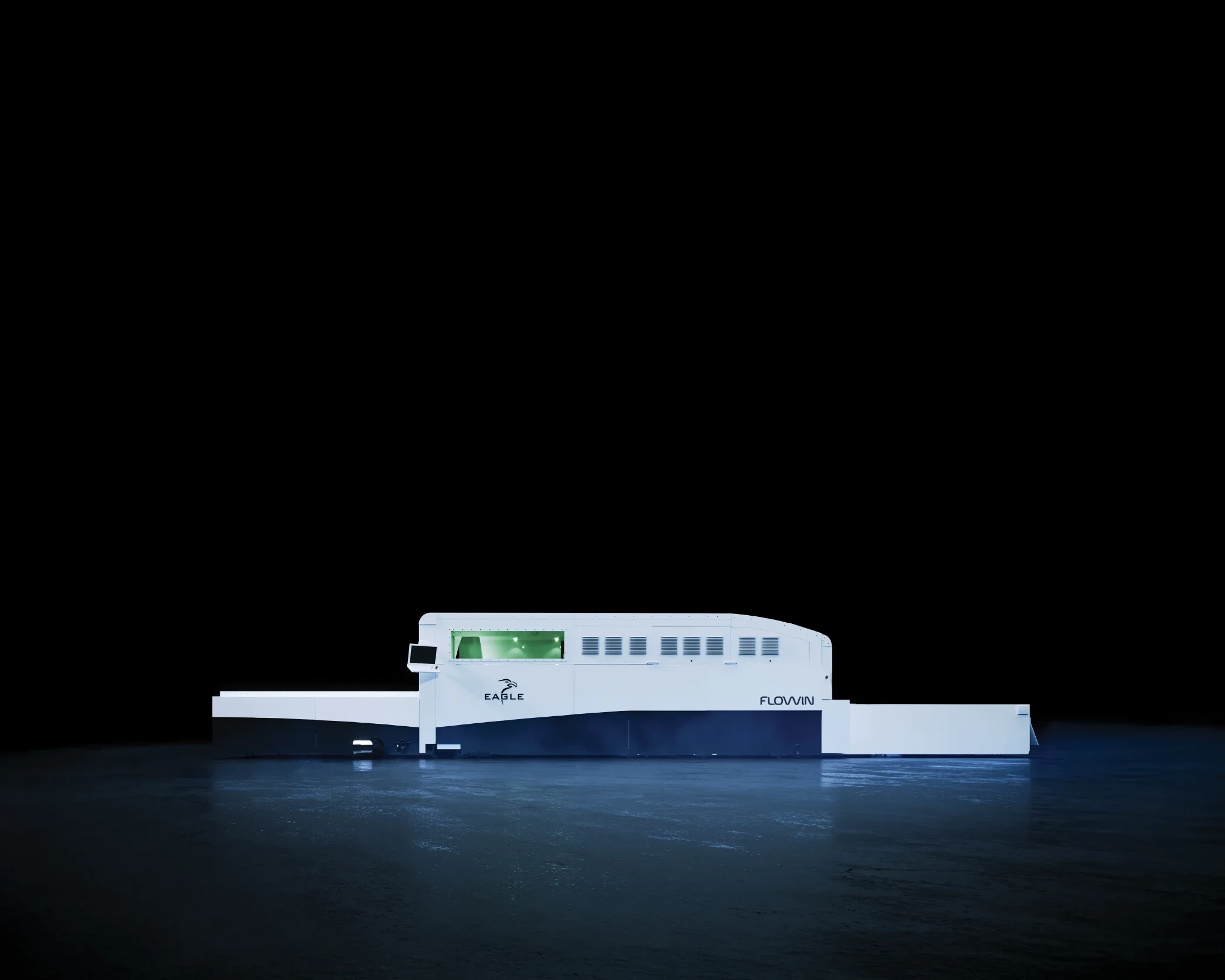

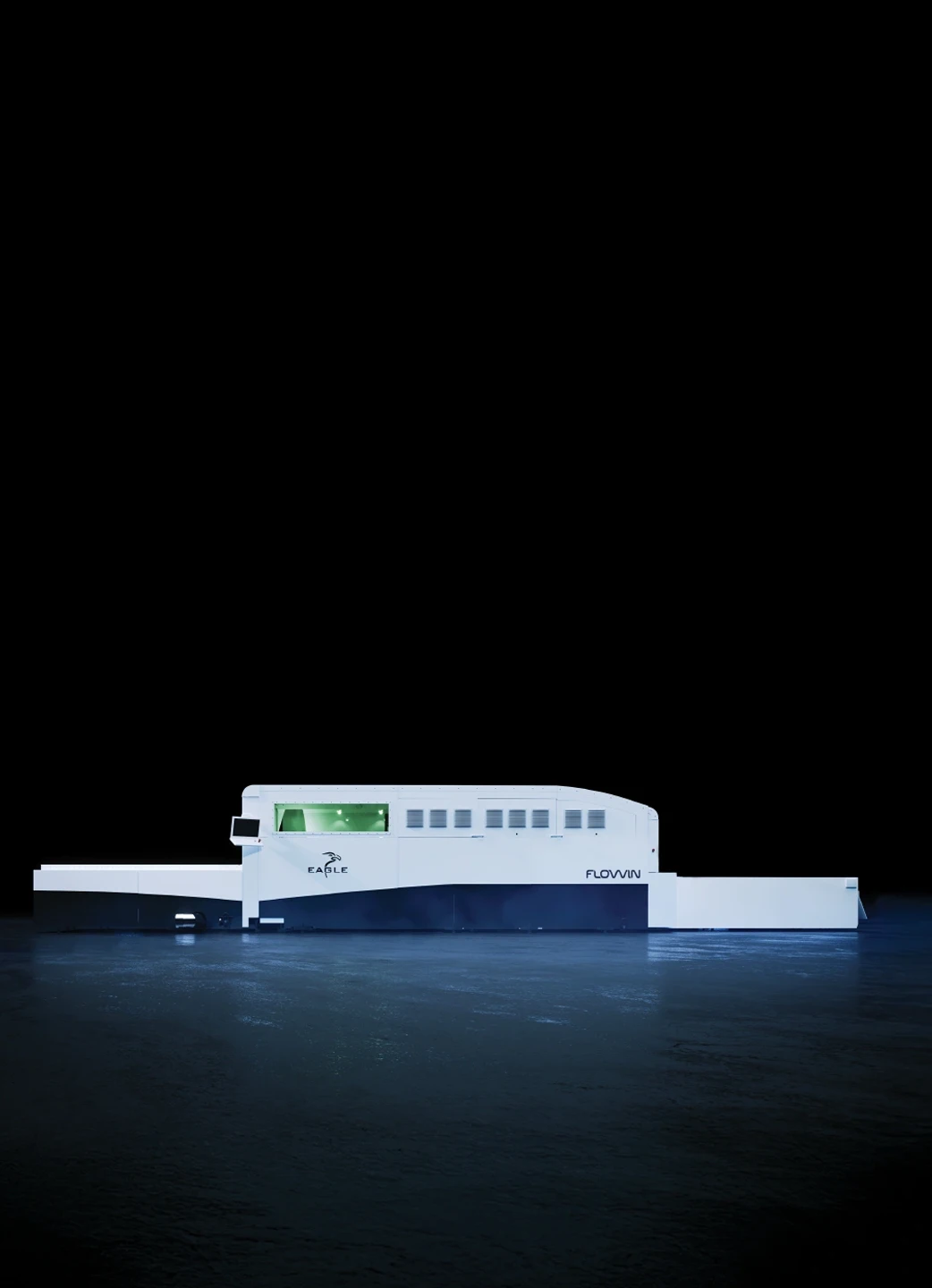

Innovation is at the core of our commitment to advancing the sheet metal cutting industry. We're excited to introduce two groundbreaking machines that are set to redefine the market. These new solutions deliver unmatched precision, speed, and efficiency, enabling businesses to reach new heights of productivity. Engineered with the latest fiber laser technology and designed for seamless integration with automation systems, the new iNspire and FlowIN are tailored to meet the evolving demands of modern manufacturing. Experience the future of sheet metal cutting, elevate your performance, and achieve greater success.

More than laser cutting

For your production to run swiftly, you need to consider all aspects and stages of the manufacturing process. At Eagle, we have thought of every piece of the puzzle and designed an entire ecosystem with the laser cutting machine at its nucleus:

We offer you a diverse product range for every aspect of metal cutting production. Discover our unique and innovative laser cutting technology and machine components specifically designed to meet your every requirement, from automatic loading systems to storage towers and more!

Laser machines

For the fastest and most accurate metal cutting

Automation

For 24/7 uninterrupted manufacturing

Storage

For flexible and modular stock solutions

Software

For remote monitoring and enhanced efficiency

Components

For maximum quality and durability

Support

For technical and financial peace of mind

eVa cutting head for the highest fiber laser performance

The cutting head is the most important component of a laser cutting machine since it has to withstand extreme conditions and be able to control ultra-high powers while maintaining top precision. Our patented eVa cutting head was built after thorough research to deliver five times less contamination, with automatic beam centering and minimal service requirements, among other unique features. The eVa is a state-of-the-art piece of engineering capable of unmatched performance.

News & Events

News & Events

Stay up to date with the latest developments in the laser cutting industry, our company news, and upcoming events.